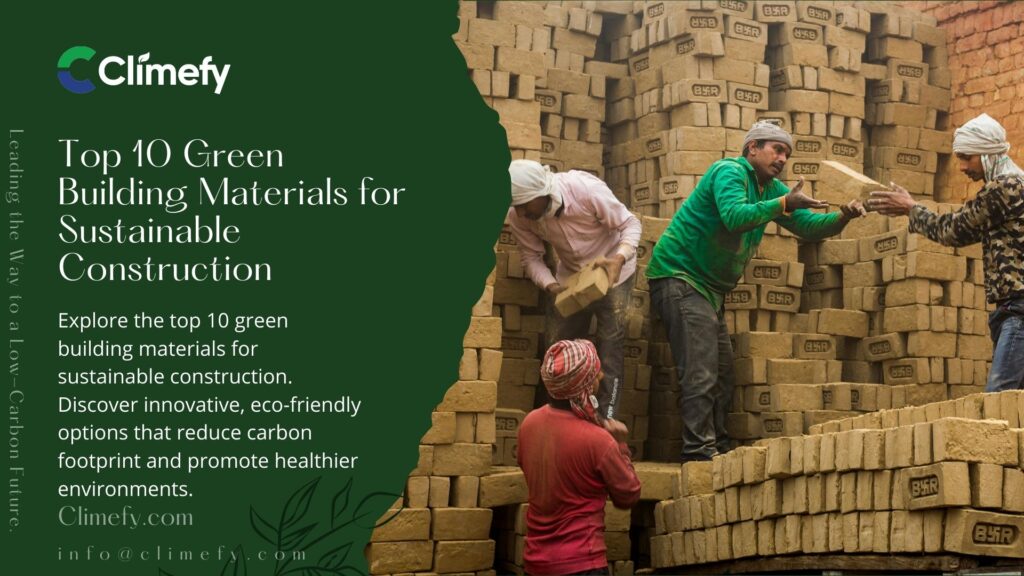

The shift toward sustainable construction is no longer a niche trend but a fundamental necessity for our planet’s future, and at the heart of this transformation are green building materials. These materials are engineered and sourced to minimise environmental impact, reduce energy consumption, and create healthier living spaces throughout their entire lifecycle. From cutting-edge, low-carbon innovations to ancient, rediscovered resources, the choices we make in construction materials directly influence our global carbon footprint and the resilience of our built environment.

In this comprehensive guide, you will learn:

Read More:

Green building materials, often referred to as sustainable or eco-friendly construction materials, are products that provide specific environmental benefits over their conventional counterparts. These benefits are assessed through a holistic Life Cycle Assessment (LCA) that examines the material’s journey from raw material extraction (cradle) through manufacturing, transportation, installation, use, maintenance, and finally to its end-of-life disposal or recycling (grave).

The core objective is to select materials that significantly reduce negative impacts on ecosystems, human health, and climate stability. The urgency for their adoption stems from the construction industry’s substantial role in global resource consumption and greenhouse gas (GHG) emissions; buildings and construction are responsible for approximately 37% of global energy-related carbon dioxide emissions.

Utilising low-impact materials is therefore a decisive action in climate change mitigation, resource conservation, and the creation of a circular economy.

The critical importance of these materials is underscored by several established facts:

Incorporating green building materials is a tangible, measurable action that directly advances an organization’s Environmental, Social, and Governance (ESG) commitments and sustainability reporting. From an environmental perspective, they reduce ecological degradation and lower carbon emissions, which can be quantified and reported.

Socially, they promote occupant health and safety, contributing to social responsibility metrics. Governance is strengthened through transparent supply chain decisions and adherence to green building certifications like LEED, BREEAM, or the Climefy Verified Carbon Standard.

For businesses embarking on a Net Zero Journey, selecting materials with verified low embodied carbon is a non-negotiable step. Companies can leverage tools like the carbon calculator for large organizations to baseline their construction-related emissions and track reduction progress, turning material procurement into a strategic climate action.

The following list ranks and details the top 10 green building materials based on their environmental performance, availability, innovation, and overall contribution to sustainable construction. This selection considers factors such as carbon sequestration potential, recyclability, renewable sourcing, and proven performance in real-world applications.

Bamboo is a rapidly renewable grass that has garnered immense popularity as a strong, versatile, and sustainable alternative to traditional hardwoods and even steel in some tensile applications. Its sustainability credentials are exceptional due to its fast growth cycle—some species can grow over three feet in a day—and its ability to regenerate from its own root system without needing replanting.

This makes it a quintessential rapidly renewable resource. When harvested responsibly, bamboo forests can sequester carbon efficiently and prevent soil erosion. Its high strength-to-weight ratio makes it suitable for structural framing, flooring, cabinetry, and decorative elements.

Key attributes and applications include:

Steel is a fundamental construction material, but its virgin production is energy-intensive and a major source of industrial carbon emissions. Using recycled steel, often with a high percentage of post-consumer and post-industrial content, transforms its environmental profile.

Recycling steel saves approximately 75% of the energy required to produce steel from raw iron ore. It diverts significant waste from landfills and reduces the demand for virgin mining. Recycled steel retains all the strength, durability, and non-combustible properties of virgin steel, making it ideal for structural frames, roofing, and reinforcing components, while directly slashing a project’s embodied carbon footprint.

The environmental and practical benefits are clear:

Hempcrete is a bio-composite material made from the inner woody core (hurd) of the hemp plant mixed with a lime-based binder. It is not used for load-bearing purposes but is cast or sprayed into walls, roofs, and floors as an insulating infill within a structural frame.

Hempcrete’s standout feature is its carbon-negative property: the hemp plant absorbs a large amount of CO2 as it grows, and the lime binder slowly re-absorbs CO2 from the atmosphere as it cures (a process called carbonation), effectively locking away more carbon than is emitted during its production and application. It offers excellent thermal insulation, moisture regulation, and fire resistance.

Its sustainable characteristics include:

Cork is harvested from the bark of the cork oak tree without felling the tree itself, making it a uniquely sustainable and renewable resource. The bark regenerates every 9-12 years, and the harvesting process actually enhances the tree’s carbon sequestration capacity. Cork forests (montados) are vital ecosystems in the Mediterranean, supporting high biodiversity.

As a building material, cork is valued for its resilience, compressibility, and excellent insulating properties—both thermal and acoustic. It is naturally fire-retardant, hypoallergenic, and resistant to mould and pests. Common applications include flooring tiles, wall coverings, acoustic panels, and sub-floor insulation.

The ecological and functional advantages are significant:

Reclaimed wood, also known as salvaged or antique wood, is lumber recovered from old buildings, barns, warehouses, bridges, and other structures destined for demolition. Using reclaimed wood prevents this high-quality material from ending up in landfills and eliminates the need to harvest new trees.

This saves the embodied energy used in felling, transporting, and processing new timber, which can be substantial. Each piece of reclaimed wood carries unique character, history, and patina that cannot be replicated with new wood. It is used for flooring, beams, panelling, furniture, and decorative features, adding aesthetic and environmental value.

Its key sustainability and value points are:

Mycelium composites represent the cutting edge of biofabrication in construction. Mycelium is the root network of fungi. By growing it on agricultural waste substrates (like hemp hurds or sawdust) in moulded forms, it creates a strong, lightweight, and fully biodegradable material.

Once dried, the mycelium acts as a natural binder, creating insulating boards, acoustic panels, and even structural bricks. At the end of its life, the product can be composted, returning nutrients to the soil and creating a completely circular, no-waste lifecycle. This innovation points toward a future where buildings can be “grown” with minimal energy input and environmental disruption.

The revolutionary aspects of mycelium materials include:

Rammed earth is an ancient building technique that has been modernized for contemporary sustainable construction. It involves compacting a damp mixture of earth (clay, sand, gravel, and sometimes a small amount of cement or lime as a stabiliser) into formwork to create solid, monolithic walls.

The primary material—soil—is often sourced directly from the construction site or locally, minimising transportation emissions. Rammed-earth walls have exceptional thermal mass, absorbing heat during the day and releasing it at night, which stabilises indoor temperatures and reduces reliance on mechanical heating and cooling. They are extremely durable, fireproof, and non-toxic.

The enduring benefits of rammed earth construction are:

Structural Insulated Panels (SIPs) are high-performance building panels used for walls, roofs, and floors. They consist of an insulating foam core (typically expanded polystyrene or polyisocyanurate) sandwiched between two structural facings, usually oriented strand board (OSB). SIPs create an extremely well-insulated, airtight building envelope in one step.

This superior envelope dramatically reduces air infiltration and thermal bridging, which are major sources of energy loss in conventionally framed buildings. The result is a structure that requires significantly less energy to heat and cool, aligning perfectly with passive house standards and aggressive energy efficiency targets.

The efficiency and performance advantages of SIPs include:

Windows are critical weak points in a building’s thermal envelope. Low-Emissivity (Low-E) glass has a microscopically thin, transparent coating that reflects infrared heat while allowing visible light to pass through. This keeps interiors warmer in winter by reflecting interior heat back inside and cooler in summer by reflecting exterior solar heat away.

Smart glass (or electrochromic glass) takes this further, allowing users to electronically tint the glass on demand, dynamically controlling solar heat gain and glare. These technologies drastically reduce the energy loads for HVAC systems, enhance occupant comfort, and maximize the use of natural daylight.

The transformative impact of advanced glazing includes:

Ferrock is an emerging, carbon-negative alternative to traditional Portland cement-based concrete. It is made primarily from recycled materials, including steel dust (a waste product from industrial processes) and silica from ground glass. The most remarkable property of Ferrock is that it hardens and gains strength by chemically reacting with carbon dioxide, permanently sequestering it within the material matrix.

This process makes it stronger than traditional concrete in compression and more flexible, reducing cracking. Its production uses industrial waste and absorbs CO2, positioning it as a potential game-changer for carbon-intensive applications like foundations, paving, and marine structures.

The innovative and environmental properties of Ferrock are:

Selecting the most appropriate green building materials requires a systematic evaluation that goes beyond a simple product label. It involves analyzing the material’s life cycle, local context, performance requirements, and verification of sustainability claims. A holistic approach ensures that the material choices deliver genuine environmental benefits without compromising on quality, budget, or building performance. This process is integral to any credible ESG Consultancy framework for the construction sector.

A comprehensive material selection checklist should include:

Even with the most diligent material selection, some level of residual embodied carbon is often unavoidable in a construction project. This is where the voluntary carbon market plays a critical role.

High-quality carbon offsets allow project developers to finance equivalent greenhouse gas reduction or removal projects elsewhere, balancing their unavoidable emissions and achieving Net Zero status for the project. The key is ensuring the offsets are real, additional, permanent, and verified to a rigorous standard.

This is where partnering with a credible organization like Climefy is vital. The Climefy Verified Carbon Standard ensures that carbon credits generated from projects like afforestation and plantation or renewable energy meet the highest integrity benchmarks. By purchasing verified offsets through the Climefy marketplace, construction firms can take full responsibility for their project’s carbon footprint, making their use of green building materials part of a comprehensive climate action strategy.

There is no single “most sustainable” material, as it depends on context, application, and lifecycle impacts. However, materials that are rapidly renewable and sequester carbon, like bamboo and hempcrete, or those that are abundantly recycled, like steel, are often top contenders. The most sustainable choice is one that is locally sourced, has low embodied carbon, and is appropriate for the specific structural and climatic needs of the project.

While some premium innovative materials can have higher upfront costs, many, like recycled content products, are cost-competitive. It’s crucial to consider total cost of ownership. Green materials often lead to significant long-term savings through reduced energy bills, lower maintenance costs, and potential tax incentives or certification benefits. Furthermore, as demand grows and production scales, prices continue to become more accessible.

Look for transparent, third-party verified documentation. Key documents include Environmental Product Declarations (EPDs), which provide standardized LCA data, and certifications from reputable organizations like Forest Stewardship Council (FSC) for wood, Cradle to Cradle Certified, or Declare labels. Be wary of vague marketing terms like “eco-friendly” without substantiating evidence.

Absolutely. From residential homes to commercial skyscrapers and infrastructure projects, there are green material alternatives for nearly every application. The market now offers sustainable options for structural systems, insulation, cladding, interior finishes, and even roofing. Innovation in areas like mass timber (CLT) is enabling taller wooden structures, while recycled steel remains a staple for large commercial builds.

Using green building materials is a primary way to earn points in major green building rating systems. In LEED, credits are available for using materials with recycled content, rapidly renewable materials, bio-based materials, locally sourced materials, and products with verified EPDs. Material selection directly impacts credits in the “Materials and Resources” and “Indoor Environmental Quality” categories, often forming a significant portion of the points needed for certification.